You’re accessing archived content

This is archived content from the UIT website. Information may be outdated, and links may no longer function. Please contact stratcomm@it.utah.edu if you have any questions about archived content.

Meet Your Colleagues: Fiber Team

Clockwise from top left: Tim Goodale, Zack Gutierrez, Brayden Ashton, Brandon West, and Destry Mulleneaux. Not pictured: Doug Conorich.

More than 38 million feet of fiber-optic cable wind around the University of Utah. That's approximately 7,200 miles, roughly the distance from Salt Lake City to Hong Kong.

Fiber-optic cables are hair-thin glass threads that connect phones and devices to campus networks, allowing data to travel longer distances and at higher bandwidths than other cables. Where copper cabling uses electricity to transmit signals, fiber-optics use light pulses to do the same thing.

Reliable fiber is mission-critical at a Research 1 (R1) university like the U. Besides bandwidth-heavy projects like POWDER, a testbed for next-generation wireless research, hospital and patient care systems rely on fiber connections, too. This requires the Fiber Team in UIT Communications Infrastructure to remain available 24/7/365, working on a rotating on-call schedule.

"Dr. Smith doesn’t know what goes on in background, and he doesn't have to. Our job is to make his connections seamless so there's not so much as a blip," Fiber Technician Zack Gutierrez said.

COVID-19 has caused the team to pivot but hasn’t slowed them down a bit.

"We haven’t been this busy since the [2002 Winter] Olympics," Tim Goodale, Cable Plant senior product manager, said.

So everyone stays healthy and business isn't interrupted, Goodale said they've increasingly divvied up on-site installation work, hired additional contractors, and conducted managerial duties remotely. The Cable Plant group, he said, is currently divided into two teams of fiber and copper techs, one managed by Fiber Team Supervisor Destry Mulleneaux, who works exclusively from home.

"For us, the risk of exposure [to the virus] is equivalent to the medical field, and we can't let one person take the whole team down," Goodale said, noting that two team members — Doug Conorich and Brandon West — are installing copper cable full time to cover staffing limitations.

Social distance has been a minor strain on a close-knit team.

"We're like a family," Goodale said, with Gutierrez adding, "Everyone’s willing to help out … these guys are just on it. It's a total team effort."

"The camaraderie we have, and the support from Tim, it's special."

The team effort extends to smaller jobs like campus building remodels all the way to high-stakes, high-profile initiatives like the Ambulatory Care Complex (ACC) project, and most recently, the sprawling Kahlert Village residential housing project, which involved 832 fiber splices.

"That was a lot,” Gutierrez said. “That building is very well-connected."

West said it's also been fun to test fiber connections at Rice-Eccles Stadium before football games and be on-site during events like the Motocross Nitro Circus.

"No matter what the job is — whether it's tedious or complex, especially if someone gets super frustrated, we're all there for each other to offer a new way of thinking and lend a hand," Gutierrez said.

Team members are certified in essential skills for various scenarios — from high-temperature, high-voltage, and combustible environments, to confined space, medical, and Occupational Safety and Health Administration (OSHA) training.

"We have the best-trained fiber team in the state of Utah, with the [certifications] and documentation to prove it," Goodale said. "The diversity of fiber we deal with is remarkable. These guys can walk into any fiber situation and deal with it.

"We're the largest air-blown fiber facility west of the Mississippi, and we're pretty proud of that."

Cable Plant by the numbers

Cable Plant by the numbers

- Size of campus: ~1,535 acres

- Fiber-optic cabling: 38 million+ feet

- Copper cabling: 42 million+ feet

- Most connections swung to fiber during a single project: 1,200 (converting network nodes from the Park Building to the Williams Building)

Fiber team in action

In this March 2016 file photo, Fiber Team Supervisor Destry Mulleneaux descends a manhole while installing air blown fiber from the Energy and Geoscience Institute to the Dumke Health Professions Education building.

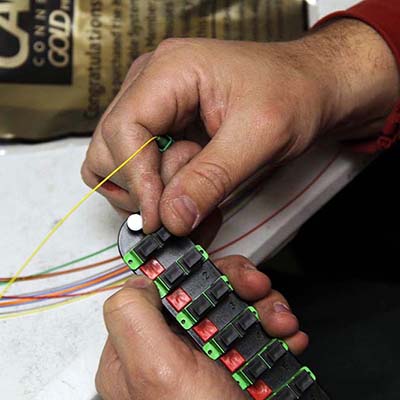

Once a feed is complete, the meticulous process of stripping, cleaning, cleaving, and fusing the fibers begins. In this file photo, optical fibers are joined to a “pigtail,” a fiber optic cable with a factory-installed connector on one end, and un-terminated fiber on the other.

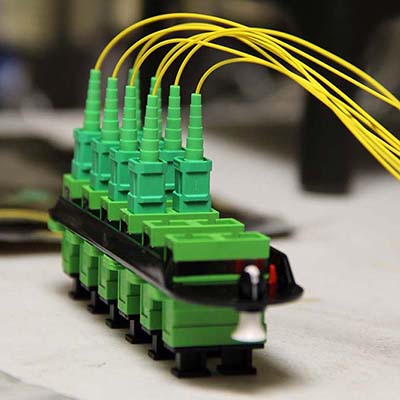

This file photo shows the connector clicked into a fiber termination unit coupler panel. After this is done, each individual length of fiber must be fused to the factory-polished fiber end of the pigtail.

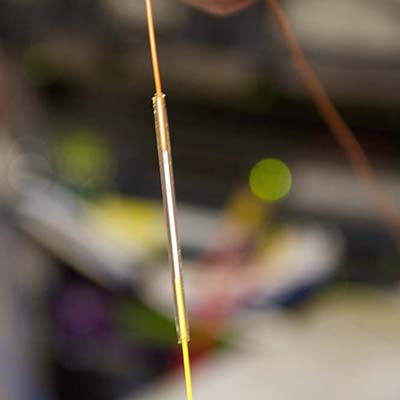

After being cleaned, the glass tips on the fusible ends are snipped with a cleaving machine that contains a cutter made of ruby, a finer edge than any metal, similar to a diamond. Both ends have to be precisely cleaved and aligned or the fusion-splicing machine will reject the splice.

The attachment process is vital to the success of the telecommunications network. Done well, it allows optical signals to pass with low attenuation (reduction in signal loss).

Node 4

Our monthly newsletter includes news from UIT and other campus/ University of Utah Health IT organizations, features about UIT employees, IT governance news, and various announcements and updates.